Strategic Plan for the Advanced Prototyping Lab

This is an ongoing strategic plan for the Advanced Prototyping Lab at Jacobs Institute for Design Innovation. I publish it here as an "evergreen" document however I do save versions of it as it is updated.

Introduction

Jacobs Institute initial purchased two industrial 3D printers for what became known as the Advanced Prototyping Lab. While these machines had utility those choosing them did not have the benefit of knowing how they would fare to our fabricators. With eight years of making, we have the benefit of seeing of how people use the tools at Jacobs and what could make it better. 3D printing has continued to evolve and the their use within educational context has as well.

History

The Advanced Lab's Mission

Our goal is to provide advanced digital fabrication technology that would not be available otherwise. This includes advanced materials and advanced prototyping techniques. These resources should be accessible to students as well as researchers.

Multiple researches have said that without the Advanced Lab, their only other option would be to spend thousands or tens of thousands of dollars for something important to their work to be fabricated. Having funding and a steadier schedules, researchers have used the Advanced Lab consistently since it began.

Since adopting the Form 3 printers, more undergraduate use the Advanced Lab. Materials are priced reasonably, the printers are reliable, and the software is intuitive.

Software Needs

-

Connectivity

- the ability for students to remotely see the status of 3D printers

- the option to manage a queue for these

-

Print job payment software that integrates with 3D printers so that payment is taken whenever someone begins a print. Currently we operate on trust and periodically checking the logs.

While these are important to the daily functions of the Advanced Lab, I have not yet found solutions for them that work well enough for us. So these remain known issues that I keep in mind until a solution comes along (or one can be made).

Physical Needs

-

Composites - The Markforged X7's ability to print fiber-reinforced Nylon has been a boon to students. Other high performance material options I'm looking for that:

- PEEK and PEKK

- Ultem - Two printers I know of that can print these are the Markforged FX20 and Stratasys Fortus 450mc

- See 3D Printing Materials#Engineering-Grade Filaments

-

Larger scale printing that can take over for the Fortus 380mc when its time comes:

- The Fortus has become the go-to printer for larger parts since it is the printer with the largest build volume (12 x 12 x 14 inches). Something larger would be ideal.

-

Space - there is currently little space to spare. It is unlikely that we can adopt a new machine without retiring something else first.

Current Capabilities

See Advanced Lab Project Highlights to see some projects that the Advanced Lab has supported.

The Advanced Lab currently supports:

-

Resin printing has been fulfilled more and more by our four Form 3 printers. These have given students access to prototypes that are relatively inexpensive, high-resolution, and made of a spectrum of materials. The Objet Connex3 and Connex2 are showing their age. They still see use by a small handful of labs.

-

Composite printing has enabled students to print very accurate, durable, and lightweight mechanical parts. The Markforged X7 is used for printing custom gears, enclosures, brackets, plates, mounting hardware, etc. It can't be overstated how useful this printer has been for engineering projects. Parts printed on this printer have the potential to be as strong as aluminum and this printer is now used frequently.

-

Large format printing has come in handy at the end of the semester when students and clubs need to print something that is too large to print on any other printer. They do this using the Stratasys Fortus 380mc. It has supported student groups to create full working prototypes, including Space Enterprise at Berkeley (SEB).

Current hardware nearing retirement

- Stratasys Fortus 380mc

- We still have a maintenance contract for this printer and the printer still prints fairly reliably. Once well maintained it tends to run for many years very reliably before some mechanical issue shows up again. So while it is running well now I'm beginning to plan for it's replacement

- Stratasys Objet350 Connex2 and Objet260 Connex3

- Usage of the polyjet (Objet) printers declined quite a bit post-COVID. Because of this and the age of the machines, we have allowed the expensive maintenance contracts to lapse on both so that we can start to plan for what can come next

Data

1. Usage of Advanced Lab 3D printers

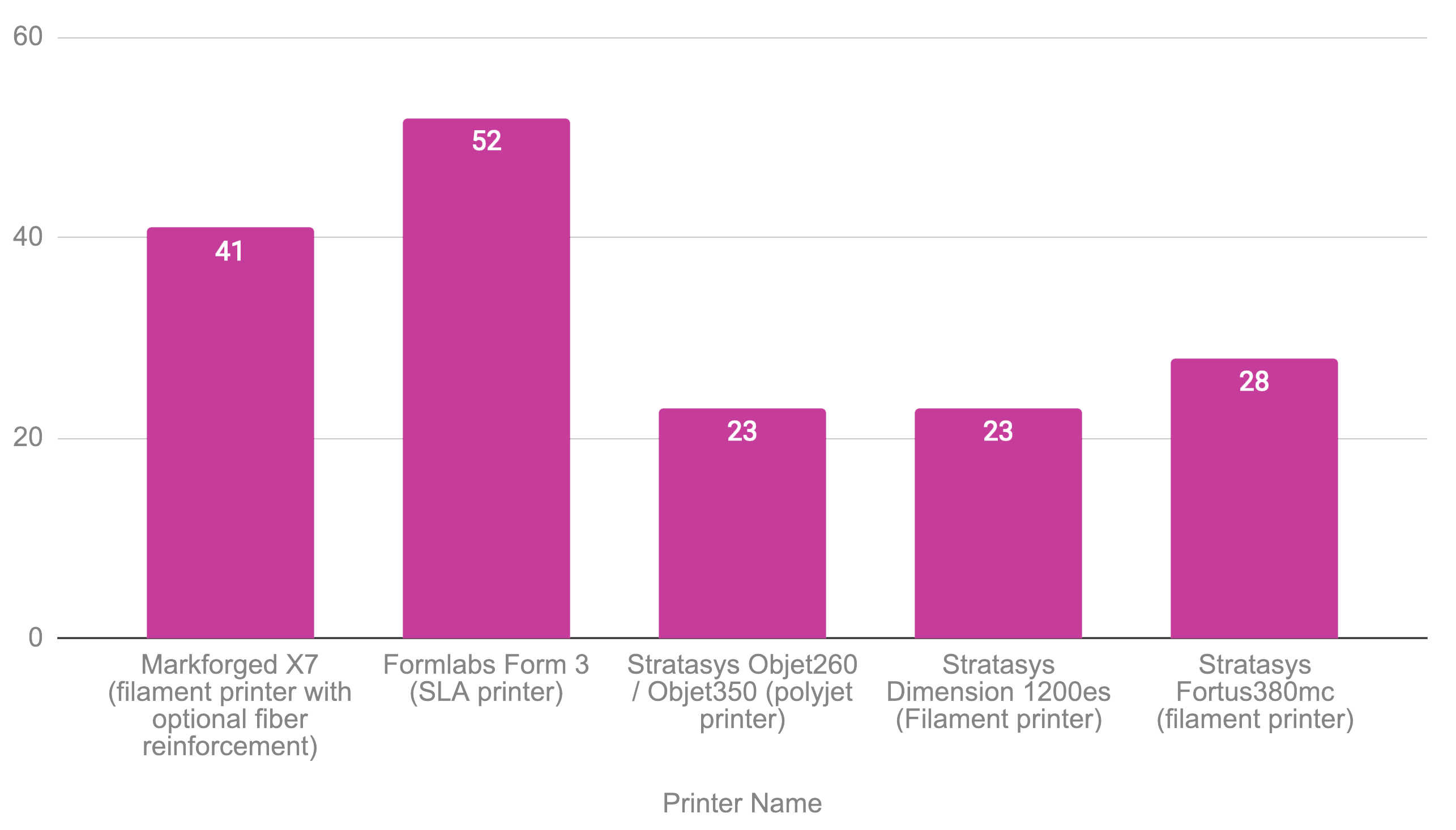

Spring 2022 JPS Submission Data for Advanced Lab printers

Fall 2022 JPS Submission Data for Advanced Lab printers

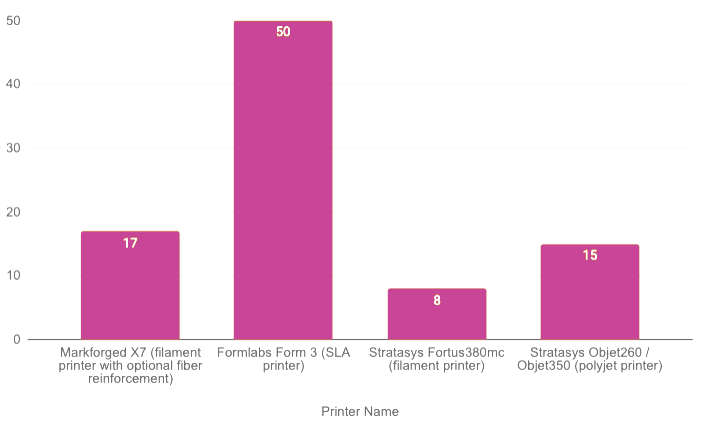

Fall 2023 JPS Submission Data for Advanced Lab printers

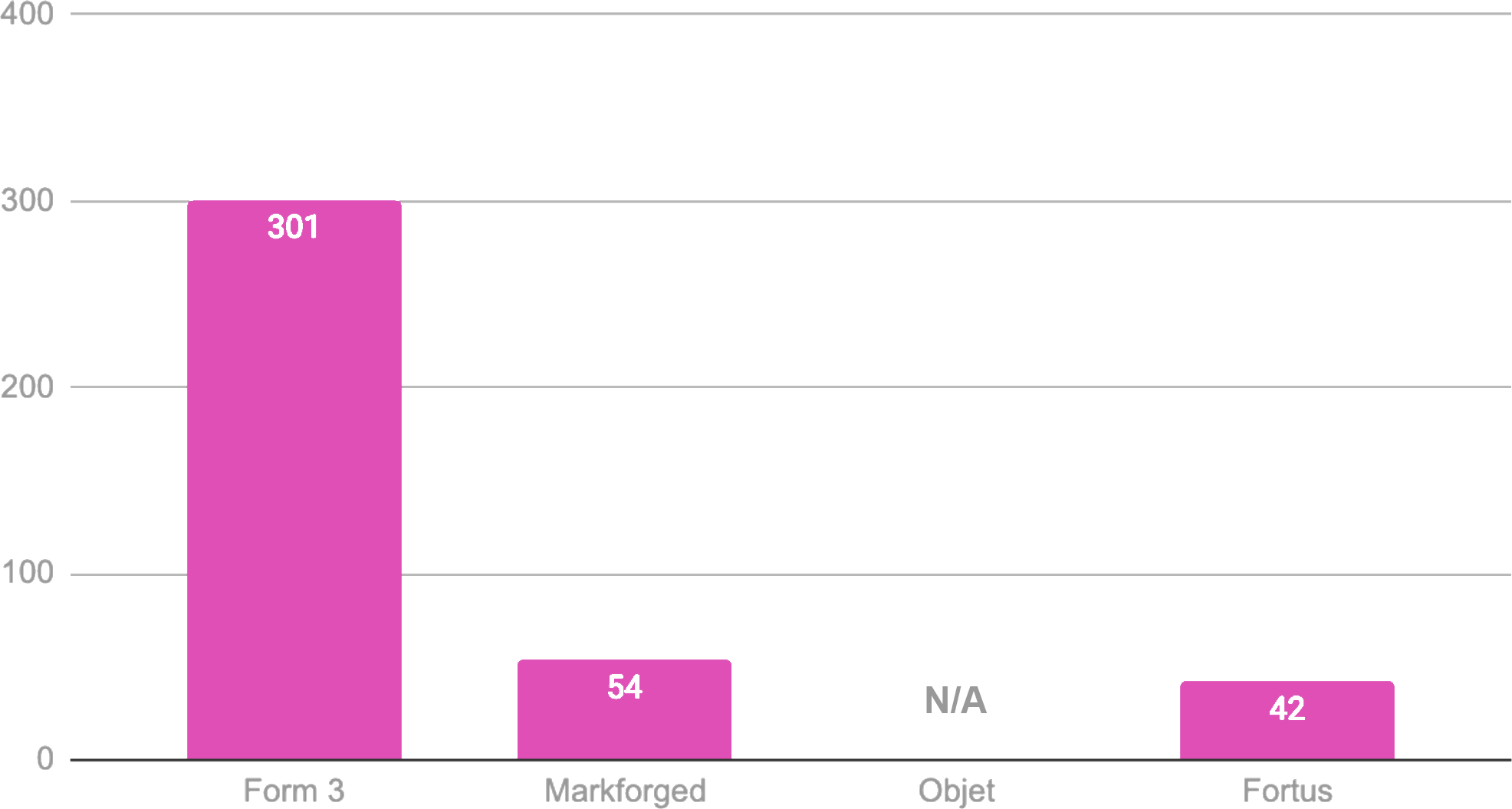

*Fall 2023 Number of print jobs on each printer

In the years following the COVID-19 Pandemic, JPS was the primary way students were utilizing the tools in Jacobs. So while JPS data does not include Maker Pass users using the machine themselves, around 2022 JPS was very active and usage data reflected very accurately was how students were using the Advanced Lab.

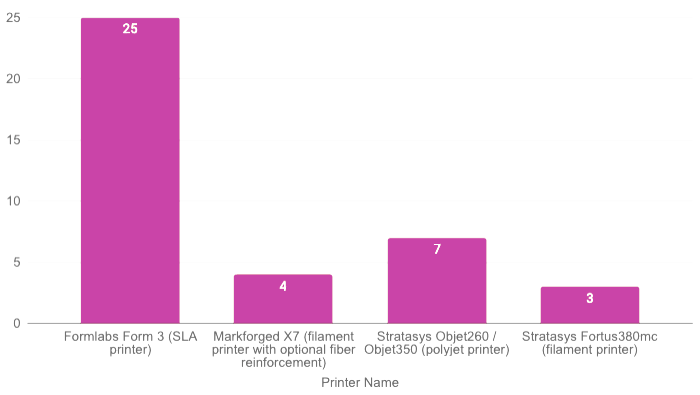

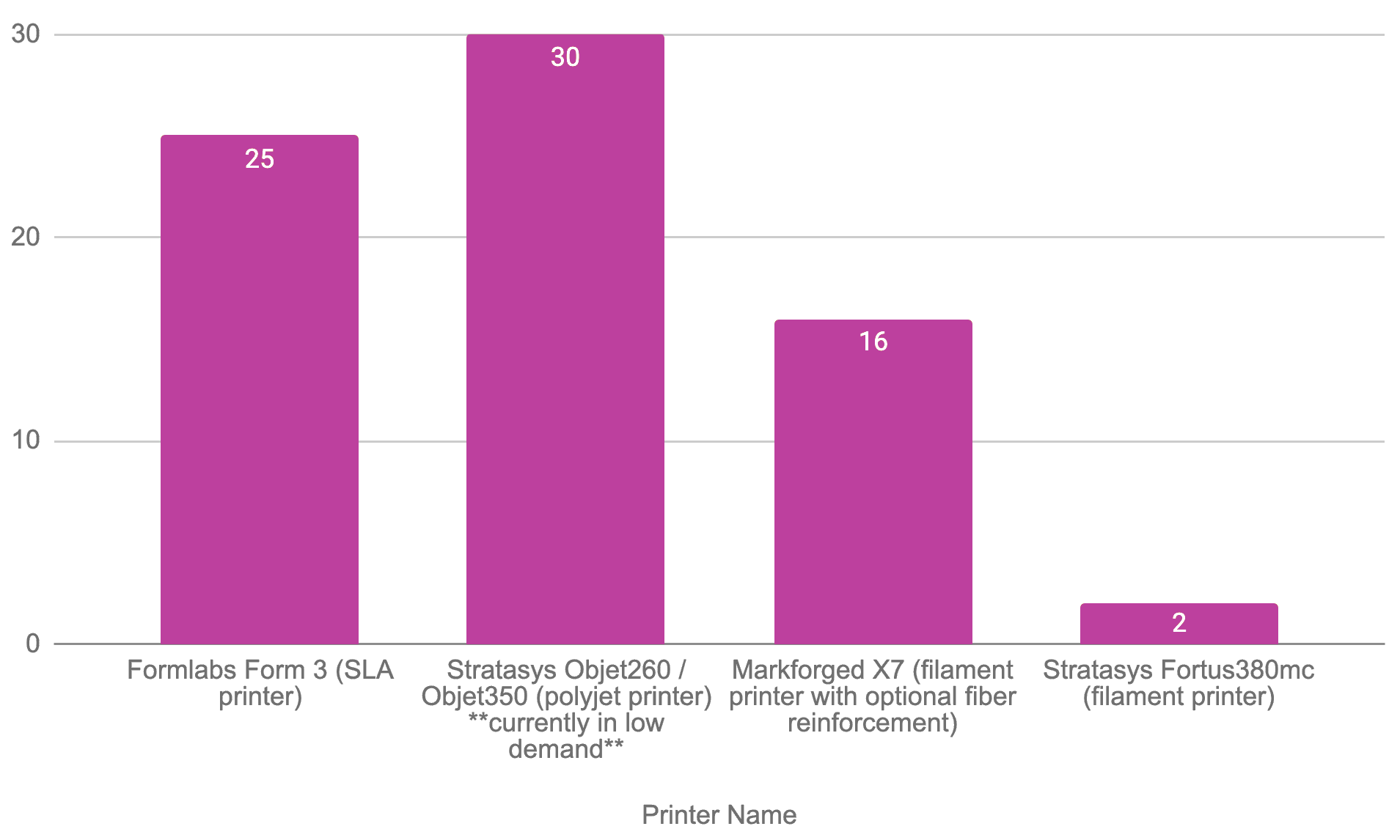

As time goes on, I still use this data to understand usage but with the caveat that Maker Pass student usage does not always reflect JPS usage. Spring 2024 (image below) shows higher Objet printer usage. In terms of print hours, the Form 3 printers were definitely the most used machines but there is currently no mechanism to capture these usage statistics of each machine.

Spring 2024 JPS Submission Data for Advanced Lab printers

2. Costs of Materials

A full comparison of costs of consumable materials in the APL can be found on this spreadsheet. Cost is an important factor in influencing how much a material will be used by students. Cutting edge technology is useless to a student who cannot afford to use it.

Highlighted Picks

These are a few 3D printers that would fit in very well with the Advanced Lab. I'm primarily evaluating this based on what these tools would provide for students. It does not necessarily take into account the availability of space in the Advanced Lab (or elsewhere in Jacobs).

| Printer | Price |

|---|---|

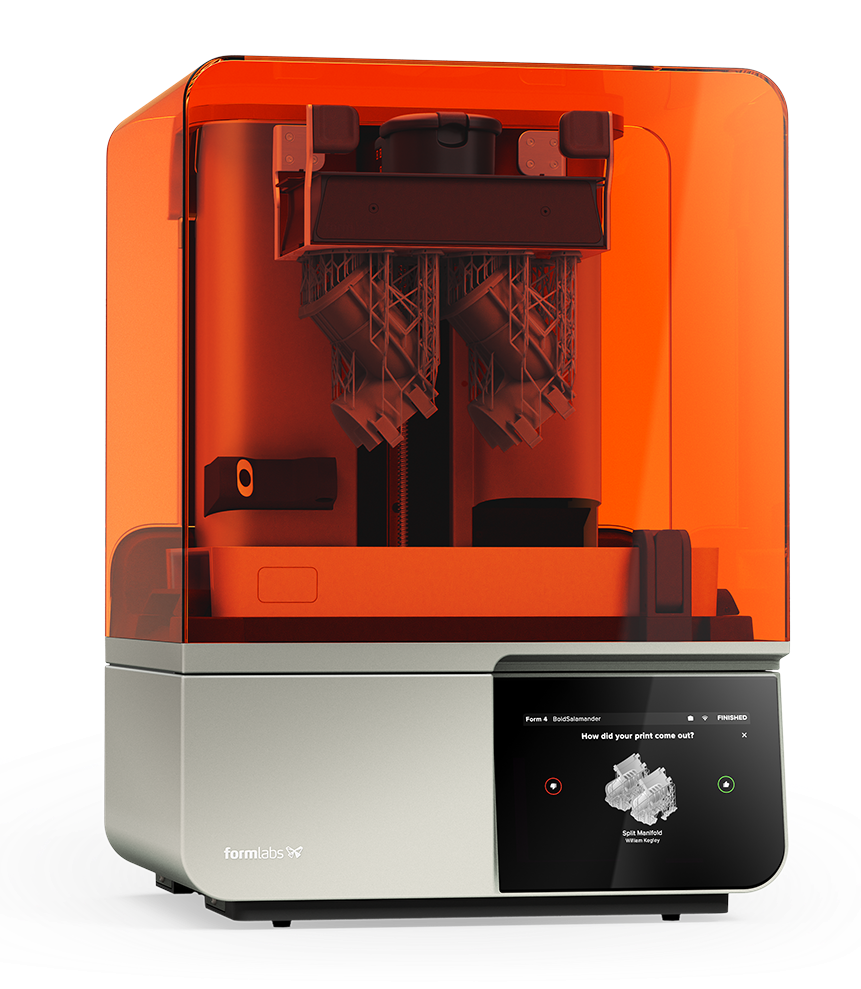

| Formlabs Form 4 | $4,499 |

| Formlabs Fuse 1 | $18,999-27,999 |

| Markforged X7 | $70,000 |

| Markforged FX10 | $99,000 |

| Stratasys Fortus 450mc | $149,000 |

Formlabs Form 4

Markforged X7

Markforged FX10

Stratasys J55 Prime

Formlabs Fuse 1+

Stratasys Fortus 450mc

Index

Here is a an exhaustive list of 3D printers that I've researched for reference.