PEEK and PEKK

Properties

- Price: $172 - $347 / lb

- high heat resistance (thermal resistance)

- Lightweight

- stronger than many metals

- wear resistance

- chemical resistance

- UL rated flame resistance

- biocompatibility

- PEKK is more flexible than PEEK

Printing Settings

| Setting | PEEK | PEKK |

|---|---|---|

| Nozzle Temp | 370 – 410 °C | 345 – 385 °C |

| Bed Temp | 120 – 160 °C | 120 – 160 °C |

| Chamber Temp | 120 – 160 °C (closed & heated chamber required) | 70 – 140 °C (lower end possible with PEKK blends) |

| Print Speed | 15 – 50 mm/s | 15 – 60 mm/s |

| Cooling Fan | Off | Off or very low (~10%) |

| Layer Height | 0.1 – 0.25 mm | 0.1 – 0.25 mm |

| Nozzle Type | Hardened steel or ruby-tipped | Same |

| Build Surface | Garolite, PEI, or carbon fiber plates with adhesive or raft | Same |

Description

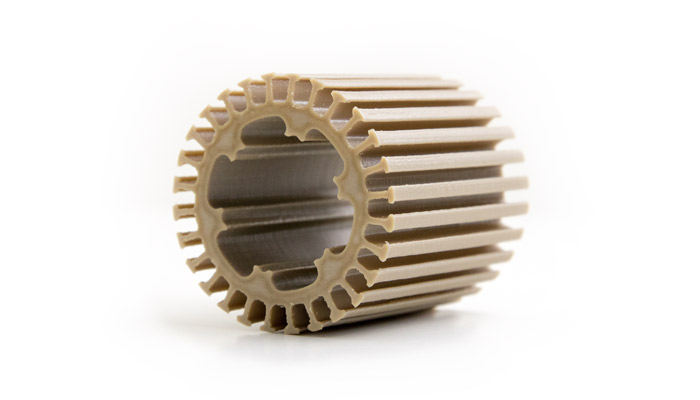

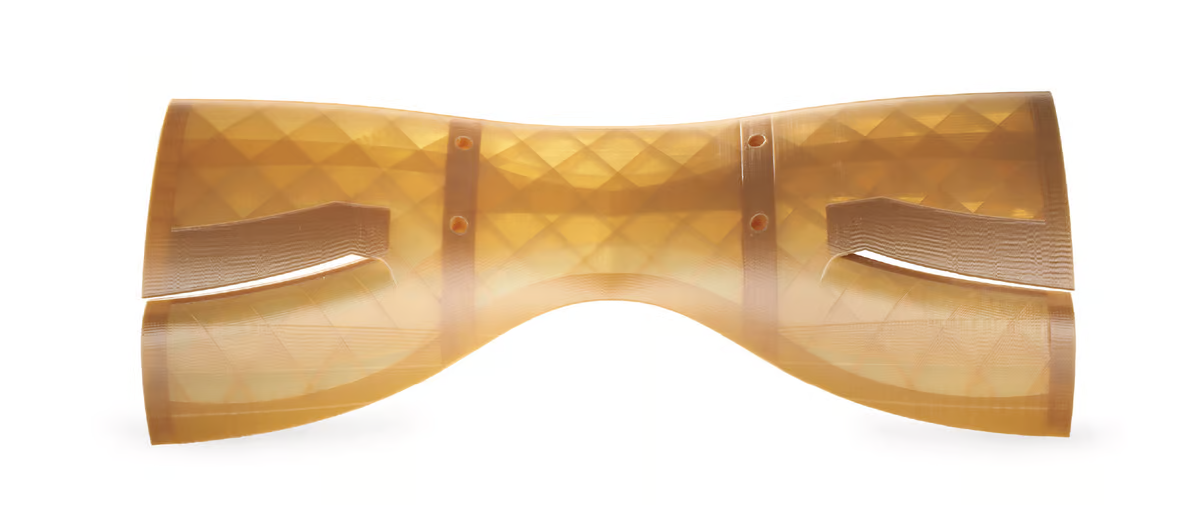

Polyether ether ketone (PEEK and PEKK) are a high-performance thermoplastic known for their exceptional chemical and temperature resistance, making them ideal for aerospace and medical applications. Polyether-ester-ketone (PEEK) and polyether-ketone-ketone (PEKK) are very similar in composition.

In 3D printing, PEEK must be printed in a high temperature environment in order to control the crystallization process. Once it cools, part of it crystallizes, changing its density. It requires an extruder that can reach 400°C, a chamber heated to 120°C, and a build plate heated to 230°C to ensure proper part release at the ending and prevent warping.

It is used in many industries to replace certain metals. Its flame resistance and high strength-to-weight ratio makes it an interesting material for aerospace. It outperforms ULTEM in mechanical strength.

Material Sources

- Victrex PEEK

- Ketaspire

- Treed Filaments PEEK NAT

- Treed Filaments PEEK CF

- Markforged Vega™: carbon fiber filled PEKK, prints on Markforged FX20

- Stratasys Victrex AM™ 200, PEEK-Based FDM Thermoplastic

Applications

- Medical sector for its sterilizability, biocompatibility - similar properties to human bone. FossiLabs and other medical device companies use PEEK for customized medical devices

- Aerospace for its flame resistance and high strength-to-weight ratio. PEEK parts have been sent to space

3D printers that can print it

- The Stratasys Fortus 450mc can print Antero 800NA,

- The Markforged FX20 can print Vega™, a carbon fiber filled PEKK

- AON M2+

- INTAMSYS FUNMAT PRO 610HT or Funmat HT

- MiniFactory Ultra 2

- Apium P400

- CreatBot PEEK-300

- More printers that can use it at All3DP

Sources

- Printing with PEEK

- All you need to know about PEEK for 3D printing

- PEEK vs PEKK: Which high performance material should I choose?

- All you need to know about PEEK for 3D printing (3D Natives)

- All you need to know about PEKK for 3D printing

See also Ultem, another high-performance thermoplastic.