3D Printing Materials

Choosing your Material

The best thing you can do is choose what material you will use before you start CAD modeling. The material and the 3D printer

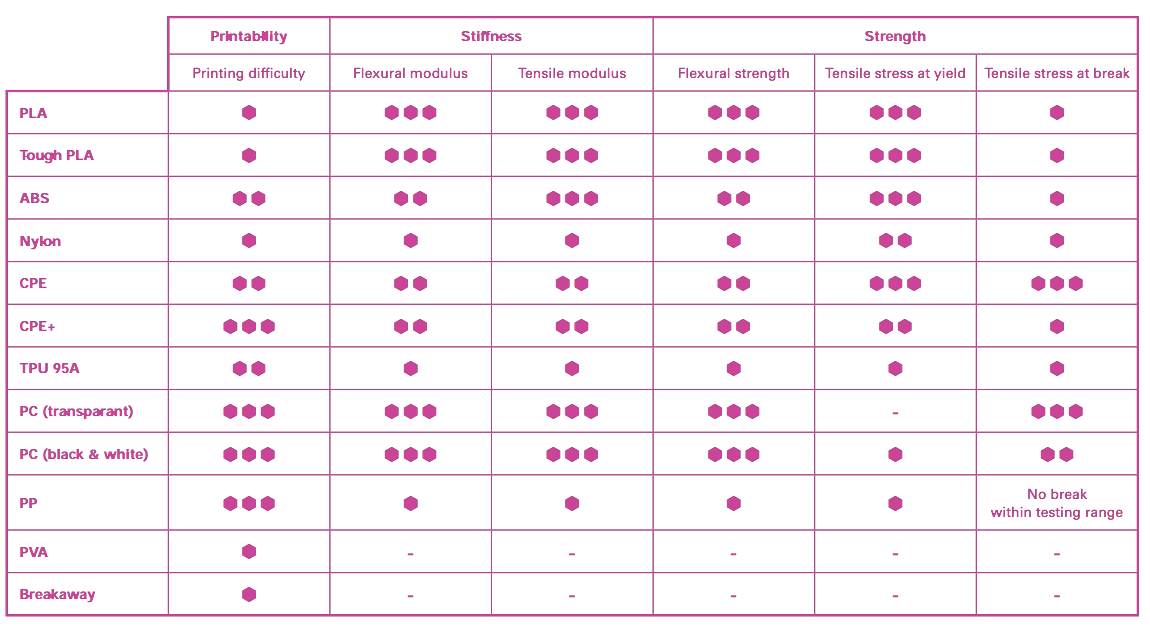

Chart courtesy of Ultimaker's How to Design for FFF 3D Printing

See also: Sustainable 3D printing materials

Standard Thermoplastics

Bio-plastics

- PLA: The standard in 3D printing prototypes - low melting temperature, comes from natural sources, non-toxic

Petroleum-based plastics

-

ABS: the second most printed filament, known for its durability and flexes well without breaking

-

PET Variants:

-

Polypropylene (PP)

-

Thermoplastic Elastomer (TPE) like TPU

-

Acrylic (PMMA): Can be printed with SLS, SLA

-

Acrylonitrile butadiene styrene (ABS)

-

Polyamide (PA)

-

Polycarbonate (PC)

-

Polyethylene (PE)

-

Polypropylene (PP)

-

Polyvinyl chloride (PVC)

Common Composite Filaments

Engineering-Grade Thermoplastics

-

Nylon: Known for its strength and durability, nylon is suitable for functional parts, especially those requiring flexibility and impact resistance.

-

PEEK and PEKK (Polyether Ether Ketone): PEEK and PEKK are a high-performance thermoplastic known for their exceptional chemical and temperature resistance, making them ideal for aerospace and medical applications.

-

PEAK

-

PPSU

-

Carbon Fiber Reinforced Filaments: Composite materials formed by infusing fragments of carbon fiber in a polymer base, making it tougher and gives it a nice matte finish.

Other Composite Filaments

- Wood Composite Filament

- Stone Filled Filament

- Algix Alga algae with PLA base $34.99 / kg

Dissolvable Support Material

PVA (Polyvinyl Alcohol): PVA is a water-soluble support material that works well with dual-extrusion 3D printers. It is often used for complex prints with intricate overhangs.

- Aquatek X1 Advanced USM Universal Support Material - Proprietary ingredients (maybe PVE?), Water soluble, supposedly be compatible with PLA, ABS, Nylon

- Stratasys SR-30, SR-100, etc. for Fortus 380mc and other filament printers

Stereolithography (SLA) Resins

Most SLA resins are based on acrylate or methacrylate monomers, forming rigid cross-linked polymer chains when exposed to UV light. Basic methacrylate SLA resins tend to be brittle, compared to flexible polymers like nylon or PETG. Check out this video of a Ph.D chemist explain 3D printer resin.

- Standard Printing Resins: Usually these are methacrylate-based photopolymers

- Engineering Grade Resins: Engineering resins for SLA printing are specially formulated to offer improved mechanical, thermal, and chemical properties compared to basic methacrylate-based SLA resins.

Bio-Compatible Materials

Medical-grade resins that are biocompatible and suitable for creating custom medical devices, dental implants, and prosthetics, or microfluidic devices. One must be careful how you print or post-process these materials. For example, If you wash bio-compatible resin in alcohol that non-bio-compatible resins were also washed in, you will contaminate the part. See Formlabs Biocompatible materials.

- PC-ISO for Stratasys Fortus 380mc

- Maybe Silicone 40A resin for Formlabs Form 3? Probably skin safe but not officially bio-compatible

- BioMed Durable Resin for Formlabs Form 3

- BioMed Elastic 50A Resin for Formlabs Form 3

- BioMed Flex 80A Resin for Formlabs Form 3

- Nylon 11 powder for Formlabs Fuse 1 SLS printer

- PU Rigid 650 Formlabs Form 3

- PU Rigid 1000 Resin for Formlabs Form 3

Color-changing and UV-Activated Filaments

These filaments change color in response to temperature or UV exposure, adding a dynamic element to printed objects.

Specialty Resins for SLA/DLP Printing

Jewelry and Casting Resins: Designed for creating intricate jewelry designs with high detail and casting.

- Formlabs Jewelry Resins

- Castable Wax 40 Resin

- Castable Wax Resin

- Grey Resin (standard resin) used for its 25 micron resolution and matte finish before casting

- High Temp Resin is strong enough to withstand the temperatures and pressures of medium temperature vulcanized rubber molding

Photopolymers for Dental Applications

Formulated for dental applications, including dental models, crowns, bridges, and orthodontic devices.

Carbon Nanotube-Enhanced Filaments

Carbon Nanotube (CNT) Filaments: CNT-enhanced filaments offer exceptional strength and electrical conductivity, making them valuable for aerospace and electronics applications.

- According to this article, 3DXTech is now selling this but I can't find it

Customized Filaments

Some advanced 3D printing shops may offer customized filament development to meet specific client requirements.

- Colorfabb - Custom colored PLA

- Filamatrix - Custom PLA, TPU, PC, Nylon, Nylon Carbon Fiber, PEEK with custom color

Other Inorganic Materials

- Ceramics: Various types of ceramics can be 3D printed, including alumina, zirconia, and porcelain. These materials are often used in applications requiring high strength, heat resistance, and biocompatibility.

- Metals

- Concrete: See Selective Paste Intrusion

- Glass: Glass can be 3D printed using techniques like binder jetting or material extrusion. This allows for the creation of intricate glass structures and designs.

- Silicates

- Minerals: Certain minerals can be processed and used in 3D printing, especially in the production of specialized materials for specific applications.

- Oxides: Various metal oxides, such as titanium dioxide or zinc oxide, can be used in 3D printing for specific applications, including electronics and coatings.