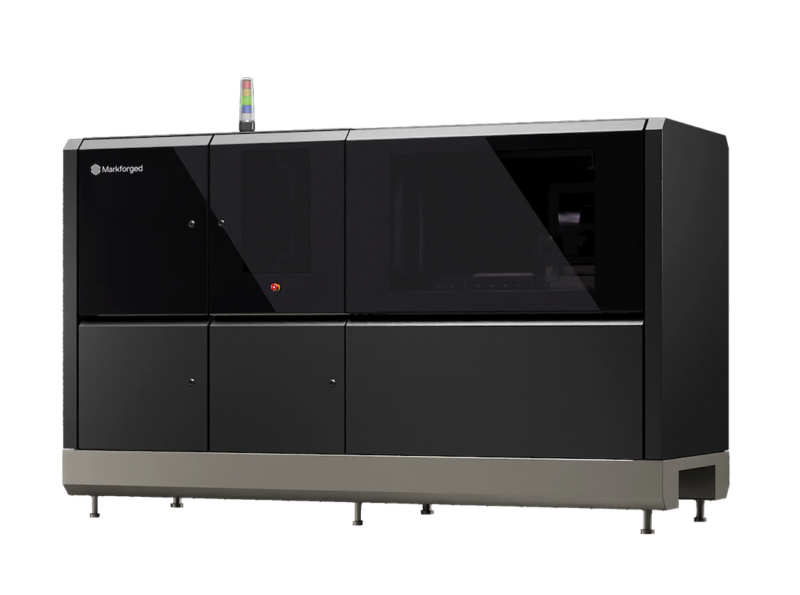

Markforged PX100

Specs

- Technology: Metal binder jetting (page-wide print system with 70,400 ink nozzles, multi-step process)

- Material Type: Metal

- Material Format: Powder feedstock

- Material Names: 17-4PH stainless steel, 316L stainless steel, 4140 steel, H13 tool steel, D2 tool steel, IN 625, IN 718, Alloy 247, Copper, Ti-6Al-4V (titanium) Material Cost:

- Build Volume:

- 9.8 x 8.5 x 2.75 in (250 × 217 × 70 mm)

- 9.8 x 8.5 x 7.3 in (250 × 217 × 186 mm)

- Price: n/a

- Resolution / Accuracy: Static accuracy better than 1 μm; resolution up to ~1600 dpi

- Link: PX100

Description

The Markforged PX100 is an industrial-grade metal 3D printer based on binder jetting technology, optimized for high-volume, precision production. Featuring a page-wide print system with 70,400 ink nozzles delivering 2 pL droplets at 15.5 kHz, it achieves ultra-fine detail with static accuracy better than 1 μm and resolutions up to 1600 dpi. Built for efficiency and flexibility, the PX100 supports a wide range of high-performance materials—including stainless steels, tool steels, nickel superalloys, copper, and titanium—with near-100% powder recirculation for minimal waste.

Its build envelope options (70 mm or 186 mm in height) make it ideal for small to mid-sized parts, while its printing speed of up to 1,000 cm³ per hour enables cost-effective production. Designed as an open and customizable system, the PX100 supports future enhancements like inertization and automation, making it a future-ready choice for sectors such as luxury goods, dental and medical, electronics, hardware manufacturing, academia, and more.