Formlabs Fuse 1

Description

The Fuse 1 is an SLS 3D printer. It works by laser-fusing powder together layer by layer. The nylon parts it produces are highly detailed, durable, flexible. The added ability to print nylon + carbon fiber gives it a more industrial quality. The unused material supports the parts during printing so you can create complex, interconnecting designs with no need for support structures. It requires the Fuse Sift for part extraction and powder recovery.

Specs

- Technology: Selective Laser sintering (SLS)

- Material Type: Elastomers, thermoplastics

- Material Format: powder

- Material Names:

- Nylon 11 ($116/kg) - highly ductile, biocompatible

- Nylon 12 ($99/kg) - versatile, biocompatible ma

- Nylon 12 GF ($108/kg) - glass fiber-filled, bio-compatible, enhanced stiffness

- Nylon 11 CF ($166/kg) - carbon fiber-filled, enhanced stiffness and strength (Fuse 1+ only)

- Polypropylene (5kg $449 - $89/kg) (Fuse 1+ only)

- TPU 90A (6kg, $799) (Fuse 1+ only)

- Build Volume: 6.49 × 6.49 × 11.8 in (165 × 165 × 300 mm)

- Printer Dimensions: 27 x 25.4 x 41.9 in (68.5 x 64.5 x 106.5 cm)

- Resolution: 0.004 in (110 microns)

- Price:

- Fuse 1: $18,999 for printer ($40,000-$50,000 for whole system)

- Fuse 1+: $28,989 for printer ($50,000- $60,000 for whole system)

- Other system requirements:

- Printer - $28,989

- Printer stand

- Fuse Sift - $10K - for excavating parts

- Fuse Blast - $11K - What would be 3 hr manual job becomes a 15-20 min automated job

- Vacuum for Fuse Sift (with negative pressure stop for explosion proofing - fire safety feature)

- Optionally, if not using Fuse Blast, a traditional media blast cabinet (see video in links)

- Skat Blast Top-Load Blast Cabinet: $949, small size to match scale of printed parts

- Optional inert atmospheric control - Limiting oxidation allows parts to have increased ductility. Options include:

- Nitrogen generator: offers continuous printing, $4K-$10K)

- Compressed gas cylinder: 10 hours of printing per cylinder, $15-30 per cylinder

- Liquid nitrogen dewar: 6-7 days of printing per 230 L dewar, $70-120 per dewar

- Service & Warranty plan

Other consumable costs:

- Replacement Air Exhaust Filter $89

- Sift HEPA Air Filter $149

- Sift 150 Sieve $89

- Sift 300 Sieve $89

Benefits to Advanced Lab

- This would add a new advanced print process (SLS)

- Higher performance laser allows for sintering Nylon 11 CF

- Low cost compared to larger, industrial SLS systems

- Ease of use

- Very low waste

- Prints parts without supports

Downsides

- powdered materials are a health hazard - would require PPE and training

- requires Fuse Sift and sandblasting cabinet to post-process

Reviews and Sources

Safety

- Source: Safety with Formlabs SLS products, SLS 3D printing fuse air quality dust hazard analysis

- PPE required:

- Eye protection

- impermeable gloves

- a mask (if ventilation is insufficient)

Quote from Formlabs Safety with Formlabs SLS products:

Airborne powder concentrations associated with normal use of the Fuse ecosystem are typically significantly below recommended and permissible exposure limits. For example, studies performed at Formlabs SLS R&D facilities, have shown that airborne powder concentrations associated with normal use of the Fuse ecosystem, even with more than a dozen printers in one room, are below 2% of the OSHA permissible exposure limit for the total particulate matter and respirable particulate matter and below 15% of the OSHA permissible exposure limit for carbon black. The normal use of the Fuse ecosystem complies with OSHA dust exposure regulations.

For more information about this study, see this air quality and dust hazard analysis (EN)

Post-Processing

- Parts need to cool down (up to half the print time for a fully packed build)

- Transfer build chamber to Fuse Sift

- Powder is sifted (and recovered)

- Parts are transferred to Fuse Blast.

- Media blasting (aka sand blasting) fully depowders SLS parts. This is particularly useful for clearing the semi-sintered "Surface Armor" out of negative features, which can be hard to reach with a brush.

See SLS Post-Processing - Extraction and media blasting for more details

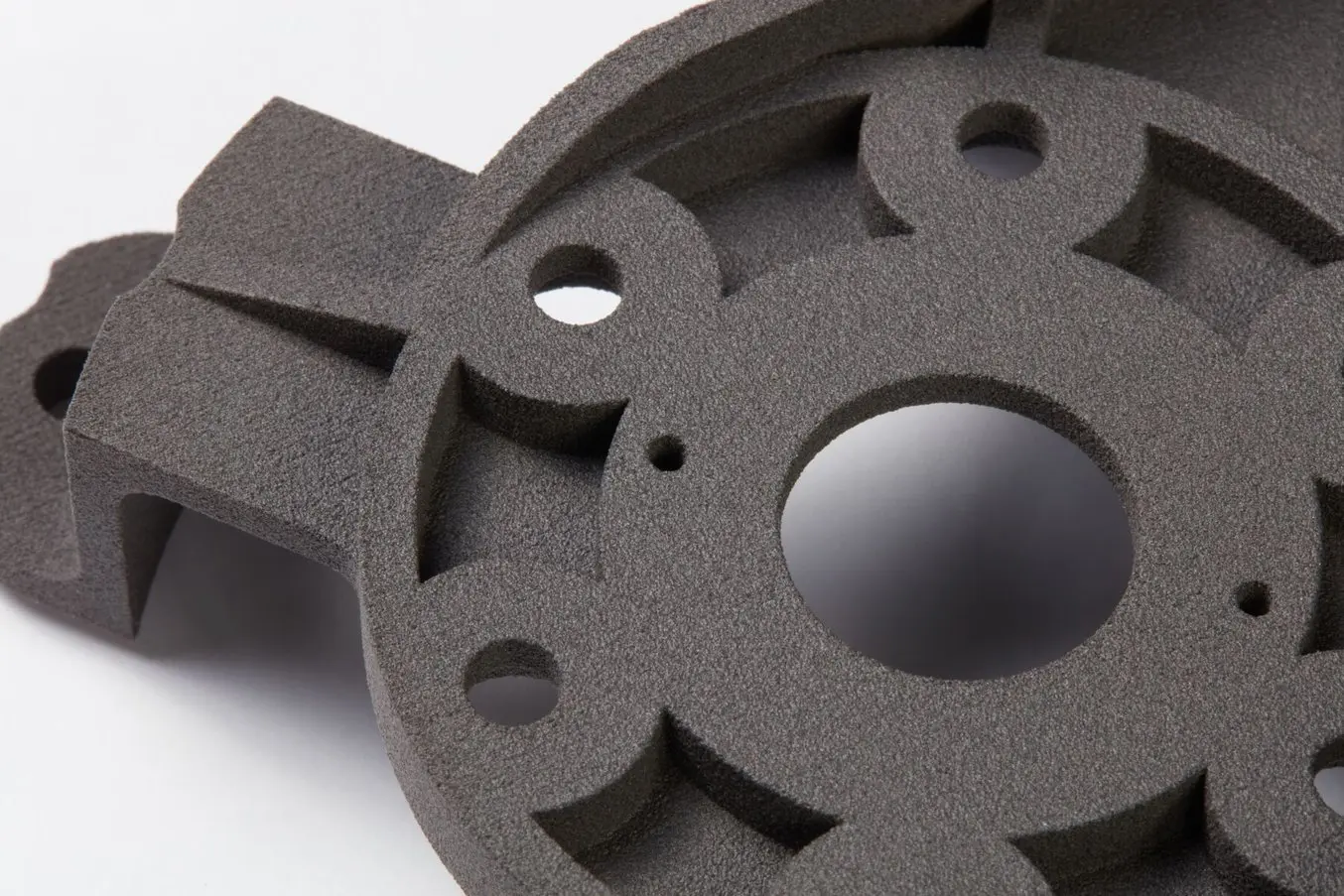

Part before media blasting

Part after media blasting

Advanced SLS Post-Processing Techniques

- Polishing (lower barrier to entry)

- Dyeing (lower barrier to entry)

- Vibratory tumbling (lower barrier to entry)

- Painting (lower barrier to entry)

- Liquid polymer coating (lower barrier to entry)

- Ceramic coating (more advanced, higher barrier to entry)

- Powder coating (more advanced, higher barrier to entry)

- Electroplating (more advanced, higher barrier to entry)

- Vapor smoothing (very advanced, very high barrier to entry)

Images

Nylon parts printed with the Fuse 1+ system