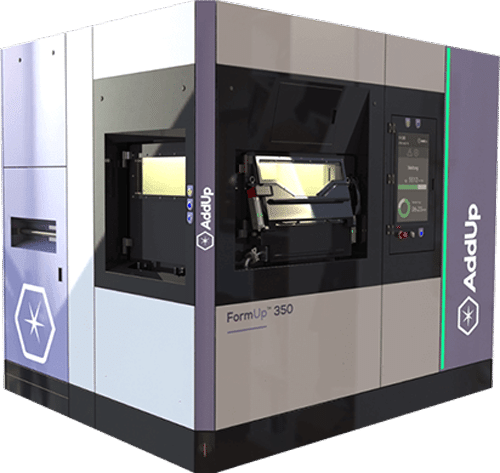

AddUp FormUp 350

Specs

Technology: Metal Powder Bed Fusion

Material Type: Metal

Material Format: powder

Material Names:

- AlSi7Mg

- AlSi10Mg

- Ti64

- Stainless Steel 316L

- Stainless steel 17-4PH

- Maraging Steel 300

- Inconel 718

- Inconel 625

- R&D possible for other alloys

Material Cost: ?

Machine Dimensions: 98.4 x 86.6 x 91.3 in (L 2.55 x W 2.2 x H 2.32 m)

Build Volume: 13.77 x 13.77 x 13.77 in (350 x 350 x 350 mm)

Price:

Resolution: Precision up to .1mm

Link: FormUp 350

Pros:

- Built in filtration for fumes and fusion residue (~3 yr filter lifetime) in V2 model

- Large build area

Cons:

- Requires respirator and likely full body suit whenever putting material in the printer or post-processing

- Requires EDM cutter

Description

The FormUp 350 machine is a solution for metal additive manufacturing using laser powder bed fusion (L-PBF). This modular and scalable machine offers a high level of productivity and allows the manufacture of high-quality parts while ensuring user safety.

Notes

The V1 machine may be better suited for research and changing materials in a shorter timeframe. The v2 keeps the powder inert better which provides a safer environment.

V1 System requirements:

Contains HVAC system (90 sec timer) and oxygen sensors.

- 11.4 x 26.25 ft (3500mm x 8000 mm) floor area for lab

- vacClean inert vacuum cleaner module

- autonomous powder module

- Print module that holds the build box

- Fluid module

- A material loading cart

- Nitrogen or argon gas supply

- ESD floor coating

- ESD footware

- Grinder for polishing build plate after jobs

Cost of materials roughly:

- Titanium $15k for 80kg ($187 / kg)

- Aluminum $5k for 80kg ($62 / kg

Powder storage:

- Store bins in firesafe cabinets, poured into bin for build module (May require sifting for removing material out of spec that could ruin machine)

Nitrogen generator possible?