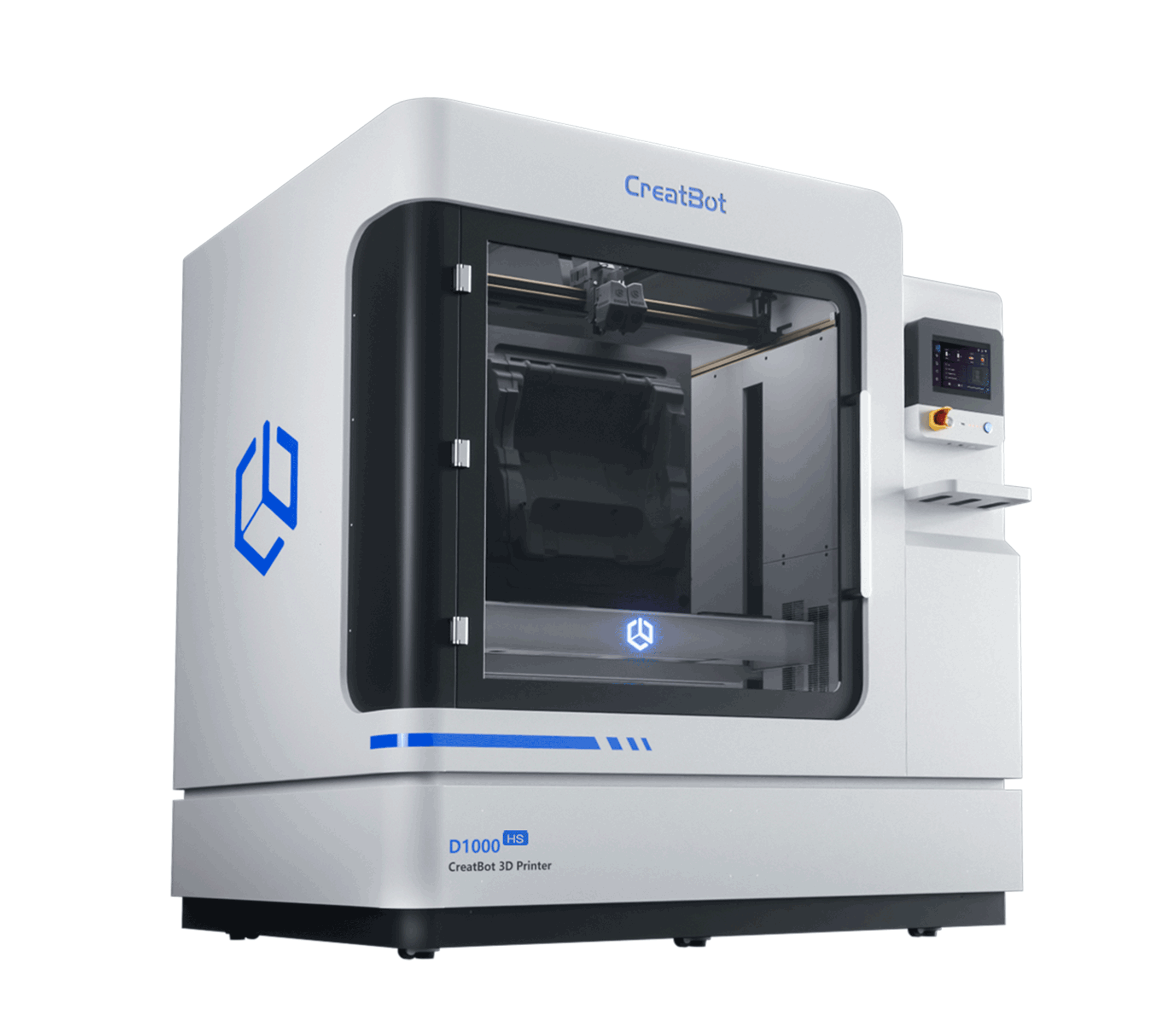

Creatbot D1000-HS

Specs

- Technology: Fused Filament Fabrication (FDM/FFF)

- Material Names:

- Standard: PLA, PLA-CF, TPU-95A, PC, WAX

- Engineering: ABS, ASA, PVDF, UltraPA, UltraPA-CF, UltraPA-GF, PET-CF

- High-Performance: PEEK, PEEK-CF, PEEK-GF, PEI-1010, PEI-9085

- Build Volume:

- Single Extrusion: 39.3 x 39.3 x 39.3 in (1 × 1 × 1 m)

- Dual Extrusion: 940 × 1000 × 1000 mm

- Print Speed / Flow Rate:

- Up to 300 mm/s sustained speed — 5× faster than previous models

- Maximum flow rate: 90 mm³/s

- Extruders: Auto-rising dual extruders; hotend temperature up to 420 °C; quick-change nozzle up to 0.8 mm standard (0.4–1.0 mm optional)

- Temperatures:

- Nozzle: up to 420 °C

- Heated Bed: up to 100 °C

- Heated Chamber: 60 °C (with built-in filament dry room 0–70 °C)

- Precision:

- XY positioning: 0.011 mm

- Z positioning: 0.0025 mm

- Motion System: Linear rail with servo motors; Klipper firmware with 5 000 mm/s² acceleration for low vibration and ultra-responsive performance

- Platform & Leveling: Aviation-grade aluminum build plate with removable magnetic surface; automatic 100-point leveling and Z-compensation

- Safety & Filtration: Fully enclosed chamber with HEPA + carbon air filtration

- Sensors & Reliability Features: Filament-out detection; automatic pause & power-loss recovery; resume from last point after interruption

- Monitoring & Control: 10″ full-color touchscreen UI with independent OS; remote monitoring via camera control and app integration

- Connectivity & Software: USB, Wi-Fi, LAN; supports CreatWare, Orca Slicer, Cura, Simplify3D, PrusaSlicer; file formats: STL, OBJ, G-code, AMF, STP, STEP

- Power & Dimensions:

- Power: 220–240 V, 50–60 Hz; Printer: 4000–5500 W; Chamber: 4500–6000 W

- Size: ~1810 × 1350 × 1942 mm; Weight: ~650 kg

- Links: Creatbot D1000-HS

- Country of Origin: China

Description

The CreatBot D1000 HS is a high-speed, industrial-scale FDM printer featuring a one-cubic-meter build volume, optimized for rapid production of full-size functional parts, large prototypes, tooling, molds, and fixtures. Powered by Klipper firmware, it achieves sustained print speeds of up to 300 mm/s and an industry-leading flow rate of 90 mm³/s—five times faster than earlier models. Dual auto-rising extruders reaching 420 °C enable material flexibility and fast nozzle changes. Its robust motion system with linear rails, high acceleration, and precise positioning ensures high-quality prints with minimal artifacts. Designed for reliability, the machine includes a heated chamber with dry filament storage, air filtration, automatic leveling, filament monitoring, power-loss recovery, and app-enabled camera control. Ideal for automotive, aerospace, and manufacturing-grade prototyping, the D1000 HS enables in-house production of large, durable parts with engineering-grade materials.